A Tale of Two Challenges – and Solutions – in Water Treatment Construction

Spartanburg Water is one of the most established water systems in South Carolina. Created in 1929 as the Spartanburg Metropolitan District, the utility has a history of delivering high-quality drinking water to customers. Spartanburg Water relies on three water treatment facilities and a well-maintained network of pumping stations, lakes, and transmission lines.

Built 96 years ago, the RB Simms Water Treatment Facility (RB Simms) includes pipes and structural elements over 100 years old. In 2019, it was time to upgrade this facility. When Spartanburg Water chose Harper General Contractors to provide Construction Manager At-Risk (CM At-Risk) services for major upgrades at the RB Simms, our team spent a lot of time with the client planning our project approach carefully. We knew, however, that this project involved some significant constraints on aging infrastructure and would require a top-notch project team that could think quickly and creatively to deliver the best possible result.

Main Photo (top of page): Aerial view of the new 64” raw water line construction at Penstock Crossing.

Working Near Aging Infrastructure Utilizing Horizontal Drilling in Granite Beside a Dam

As construction and AEC professionals know, innovative solutions and quick-thinking are tools paramount to the success of a project. Unapproved plans, unforeseen circumstances, and changing requests can require the design and construction team to offer a new solution to keep the project on track. One significant problem that needed addressing on RB Simms upgrade was the facility’s location adjacent to Municipal Reservoir #1 and its associated dam, creating a distinctive challenge when operating or updating the plant. Working closely with HDR, Inc. (HDR) as the project’s design engineer, our team developed out an approach focused on mitigating any disturbance to the reservoir while also being able to finish our project on-time.

In order to complete this project, we needed to install a new ozone system. This system would be located very close to the 100-year-old dam and the associated lines for this system would need to run from the water to the treatment facility. Even though the ground along the new pipe path was solid granite, the team did not approve blasting because of its proximity to the dam. Our team was required to go back to the drawing board to come up with a solution that would allow us to connect the pipe to the water and plant, without utilizing the unapproved pathway.

The solution resulted in the Harper team contracting a tunnel boring machine (TBM) to drill horizontally through 250’ of granite along the reservoir. Our team dug a 40’x26’ shaft to prepare for the grinding machine. Even though we made significant changes to the plan, we were not willing to jeopardize our client’s project schedule. Digging the shaft required 24/7 operations for several weeks to meet the project schedule. And at some points, it included using hand tools to remove the granite. Halfway down the shaft, the team built a rest area to provide a storage place for tools and an accessible evacuation zone if necessary. The 40’ shaft included ventilation, dewatering equipment, soil nailing, conduit, pipes, and cast-in-place concrete as added safety precautions. Leaving out even one of the safety elements could potentially compromise the integrity of the bore shaft. Even though we had a change of plans and an extremely tight schedule, our team prioritized safety and quality and did not cut corners on the delivery of this shaft. After drilling 20’-30’ per day, the machine broke ground at its designated endpoint, and the team successfully connected the two pipes.

The extra time and attention spent on finding an innovative solution to this difficult situation allowed this project to move forward. The extra care, prioritization of safety and quality, and maintenance of budget allowed this project to be a success.

Exceeding Client Expectations Using Virtual Construction

As we began the journey of making significant upgrades at RB Simms, we quickly knew that virtual construction would be part of our approach. Known for its time and cost saving advantages, virtual construction has become an increasingly popular tool utilized in the construction industry in recent years. In the water and wastewater sector, this resource is just beginning to emerge on projects.

A significant problem that needed to be addressed was the existence of layers of existing infrastructure on the site, creating a distinctive challenge when operating or updating the plant. HDR and Harper came to the table with unique approaches focused on maintaining operations of the facility during construction, addressing concerns with existing infrastructure and location of the plant, and collaborating with our client throughout the entire process.

Maintaining operations during construction was a primary concern for the 64-million-gallons-per-day (MGD) plant. Simple solutions, such as building a new chemical feed storage area at the back of the plant, alleviated delivery coordination. However, installing new water lines under the existing infrastructure provided a more formidable challenge. The available plans and site layout gave a general idea of what lay underground and plant operators filled in many gaps. Still, the Harper team wanted certainty that they would not cut an electrical wire or drill through an existing water line during construction.

We performed extensive imaging and layout exercises to understand how the proposed construction would interact with underground utilities. This was accomplished using imaging technology including Total Station robotics, LiDAR imaging, and traditional sample boring. The result was a 3D model of the entire construction site, showing existing electrical, water, and utility lines laid over the proposed additions. We reviewed the model, quickly identified potential clashes, and revised the drawings accordingly. Seeing the finished product before procurement or construction and adjusting plans accordingly saved time and cost by eliminating rework and extra material purchases.

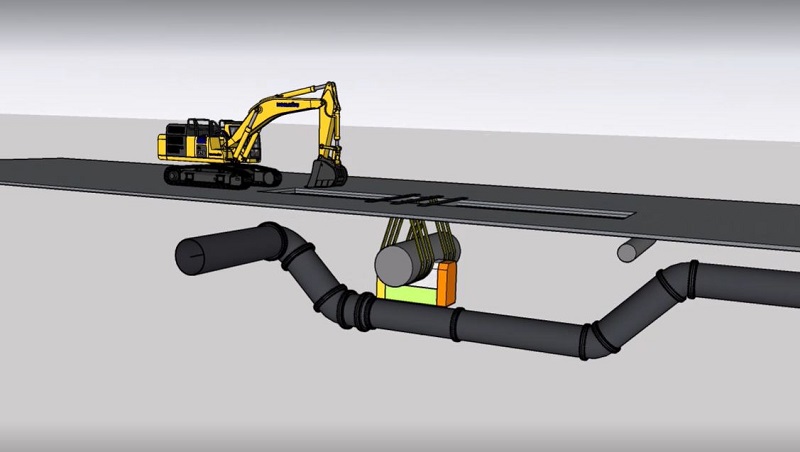

One example of the benefit of this approach was identifying that the new water and ozone lines crossed or were adjacent to an existing 100-year-old 78” penstock. The accurate site layout provided the team with the data necessary to lay the lines around the penstock with zero service interruption. Before a shovel hit the ground, Harper’s field and project management teams knew the exact location of the penstock, where they needed to dig to avoid touching the structure, and precisely where the pipe would connect once it was across the penstock.

Another collaborative application for virtual construction was combining real-time images with approved drawings. Our project manager collected 300-600 high-quality aerial images per month using Drone Deploy. The project team laid applicable images over their corresponding drawings to show progress and confirm layout and measurements. These images guided preplanning meetings with trade partners, particularly with the BIM (Building Information Modeling) model. During the monthly Owner/Engineer/Contractor meetings, these images provided Spartanburg Water with a visualization of the project to guide conversations about progress and next steps.

Overall, virtual construction allowed this project to move forward with limited interruption to plant operations. Underground imaging avoided costly conflicts between new and existing pipes. Real-time images laid over on drawings ensured precise foundations and pipe placement. BIM models provided the backdrop for quick decision-making because all parties could see and discuss the proposed end product. And, most importantly, we were able to craft an approach that used Virtual Construction to ease our client’s concerns, prioritize their requests, and exceed their expectations.

The RB Simms Water Treatment Facility was recently completed, giving Spartanburg Water the updated facility necessary to continue to produce high-quality drinking water to their customers for years to come.

About Harper

Throughout our 72-year history, Harper has had the opportunity to develop strong professional relationships with clients across the Carolinas. By bringing to life the vision of our clients, Harper leaves a lasting impression on members of the community. The core of our company is geared toward collaborating with owners and design professionals in an open and transparent manner, enabling the owner to know how every project dollar is being invested. An award-winning company, Harper consistently receives recognition in the areas of quality, safety, environmental stewardship, and community involvement. For more information, visit harpergc.com or contact us.